Custom Cable Assemblies

GTK is a global leader in the design and manufacture of custom cable assemblies. We offer highly specialised custom cable solutions for a wide range of applications and industries, including defence, automotive, medical and industrial sectors.

Through our integrated manufacturing locations across the UK, Romania and the Far East, we provide our customers with bespoke cable assemblies that are both cost-effective and tailor-made to the highest standard.

Our extensive design and production services for our custom cable assemblies cover:

- Custom looms and wire harnesses

- Simple end-to-end assemblies

- Unique overmoulded cables

- Engineering and design support

Why choose custom cable assemblies?

Custom cable assemblies and wire harnesses have a number of associated benefits, giving OEMs the chance to improve and optimise their product designs for their intended use.

In many instances, for specialised products, stock cable options simply will not do. For example, electronics for marine use might require waterproofing, while electronics for outdoor use may require overmoulded cable assemblies or full ruggedisation.

You might also find that opting for custom cable assemblies or custom wire harnesses during the initial design stages opens up a number of new possibilities. Bundling multiple cable functions into a single assembly can remove design barriers and streamline the manufacturing process.

Ultimately, streamlining your cable manufacturing means that custom cable assemblies can save you time and money. For instance, installing one multi-function cable loom is often more efficient than trying to install multiple different cable assemblies.

Find out more about the benefits of using custom wiring harnesses

Custom cable design experts

As one of the world’s leading custom cable manufacturers, we pride ourselves on our ability to deliver any degree of customisation, in almost any quantity, on demand.

This can range from simple end-to-end cable assemblies at custom lengths, to more bespoke designs that incorporate custom connectors, sheathing, or bend radius requirements. We can also develop entirely custom wiring looms, combining multiple functions and different connector types into a single cable harness.

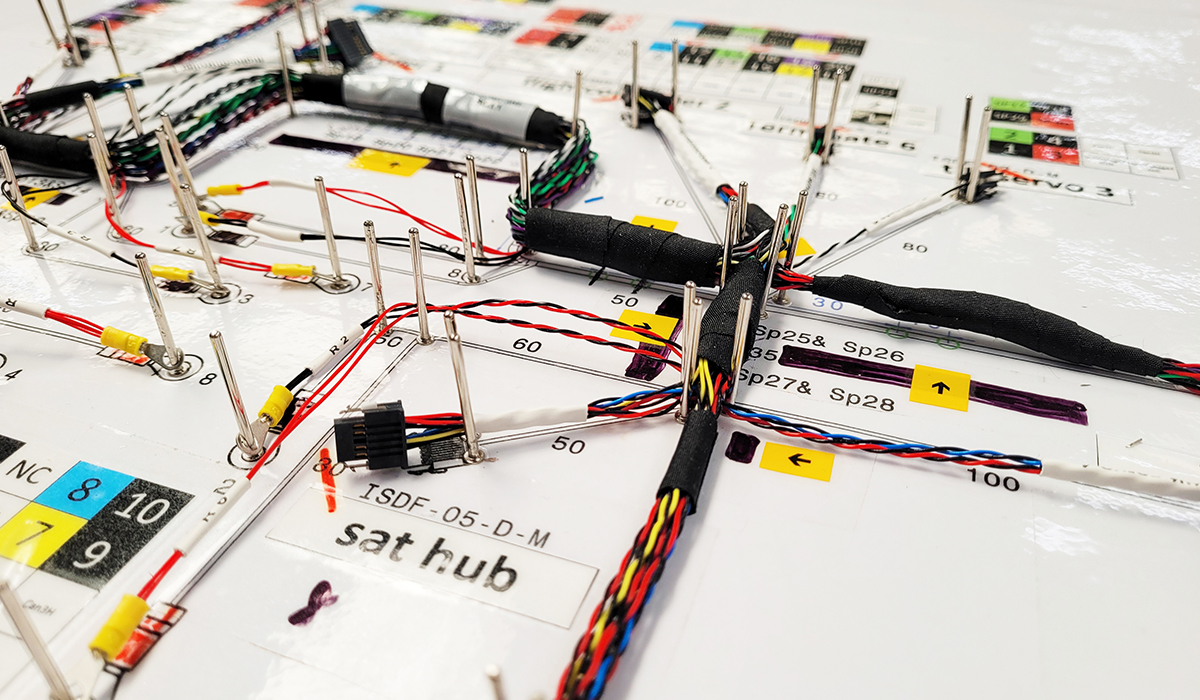

Custom Looms & Wiring Harnesses

We can manufacture a wide range of pre-formed looms and wiring harnesses – built in any size, shape, complexity and format – in order to maximise ease of installation into the finished unit.

By using pre-formed looms, the end user’s manufacturing efficiency can be massively improved, saving both time and money. Our custom wire harnesses and bespoke cable assemblies can be manufactured to any specification, and we even hold specialist certifications for sectors like aerospace and defence (AS9100).

Our offering includes:

- Manufacturing consistency through the use of loom boards

- The incorporation of any type of connector or cable

- A variety of loom forming methods, including:

- Lacing

- Braiding

- Tubing

- Spiral wrap

- Twisted wires

- Acetate or PTFE tape

- Cable ties

- Tie bases

Simple Custom Cable Assemblies

Simple cable assemblies include external cabling, internal wiring and ribbon cables. These assemblies can be used as input/output assemblies, power distribution wiring, or earthing connections.

We can utilise any major manufacturers’ connectors and offer overmoulded solutions where appropriate.

Our offering includes:

- The combination of different technologies, such as multicore cable, ribbon cable or discreet wires

- Anything from simple, prepared wire terminators to military specification connectors

- Wire sizing from 36 AWG upwards and connector pitches from 0.5mm

- An extensive range of crimp tooling, along with solder and IDC/IDT capabilities

- Additional components, such as fans, filters, ferrites and PCBs.

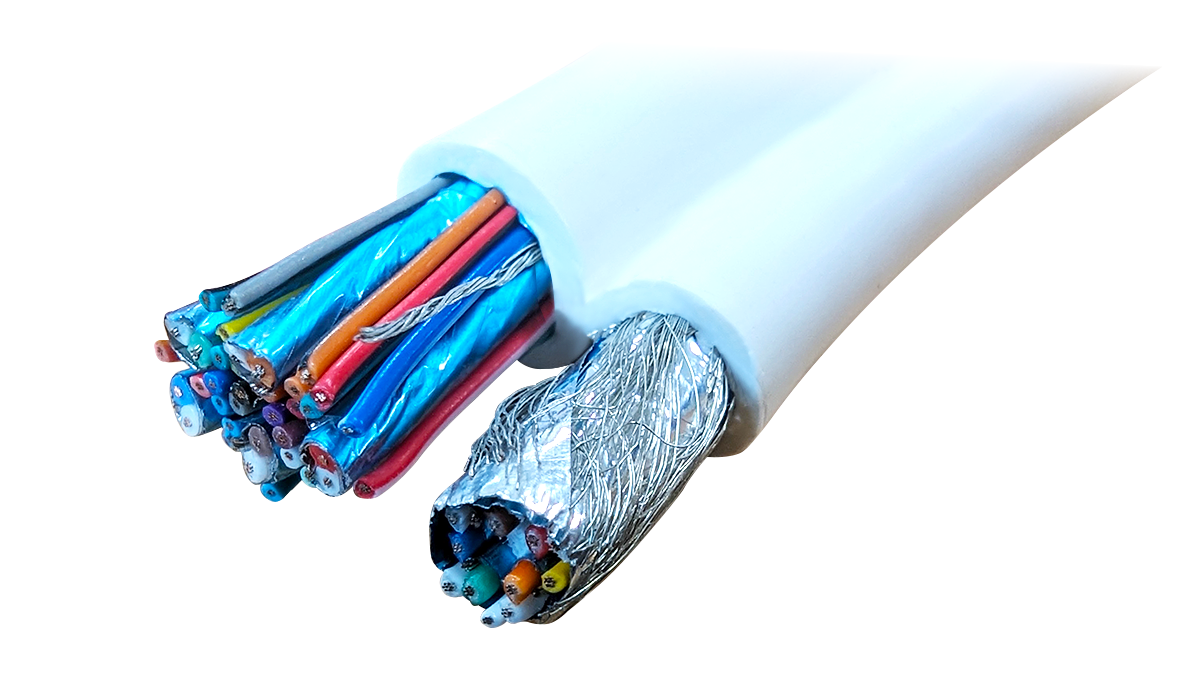

Custom Composite Cable

We can make bespoke cable assemblies and wiring harnesses in all shapes and sizes, using any industry standard cable types. However, sometimes OEMs need to use a completely custom ‘composite’ cable, which we can create to specific designs.

Composite cables can be made up of a combination of different wires, including:

- Simple insulated wires

- Twisted pairs of wires

- Shielded and braided wires

- Any other wires needed for the specific application

These wires can even be separated into different channels and extruded into a single outer sheath, where the individual channels are bonded together.

Composite cables are ideal for designs where OEMs need to combine different cable assemblies into a single harness. They can also help to simplify the process of cable routing or installation.

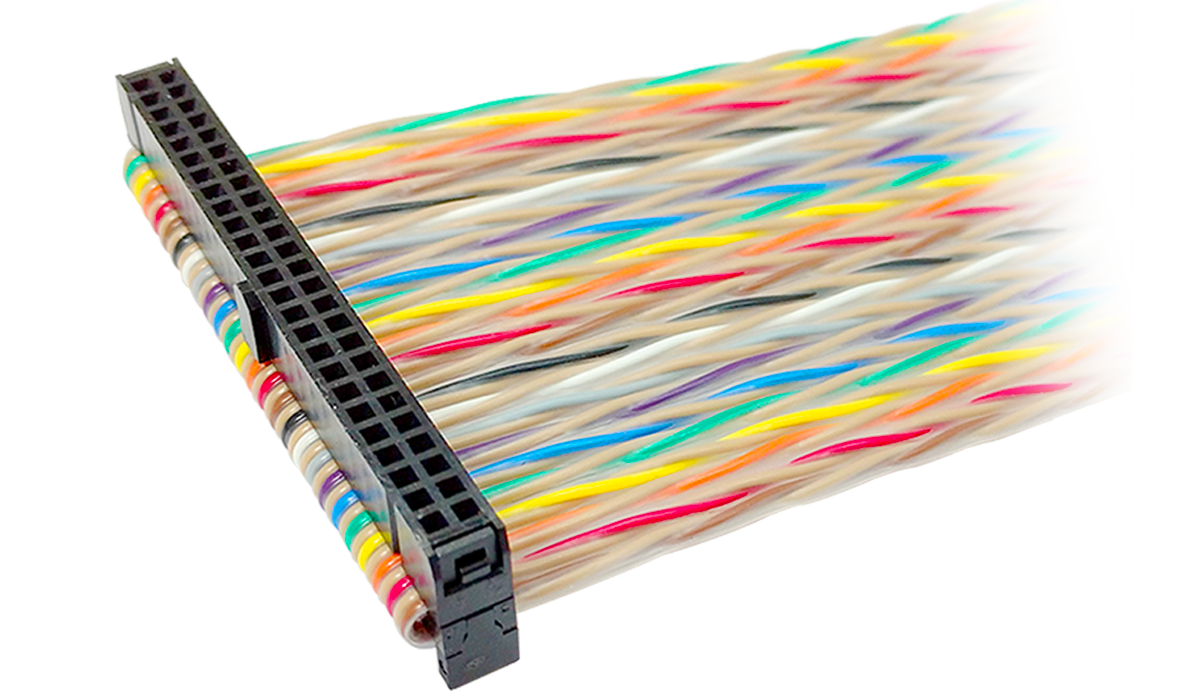

Custom Ribbon Cable Assemblies

Ribbon cables are a space-efficient method of internal board-to-board connection, that benefit from high flexibility in a low-profile form. We can manufacture flat ribbon cables terminated with IDC, IDT, crimp or solder connectors, in a wide variety of pitches, using a range of cable types.

Our custom ribbon cable assembly offering includes:

- The ability to offer low-cost alternative connectors in standard pitches, such as 2.54 mm (0.1”), as well as in conjunction with major manufacturers’ connectors

- The ability to supply assemblies pre-folded to ease routing in the final product assembly, saving time and money

- Different cable types, such as:

- Standard ribbon

- Colour coded

- Twist-and-flat

- Round-and-flat

- High-flex

- Screened

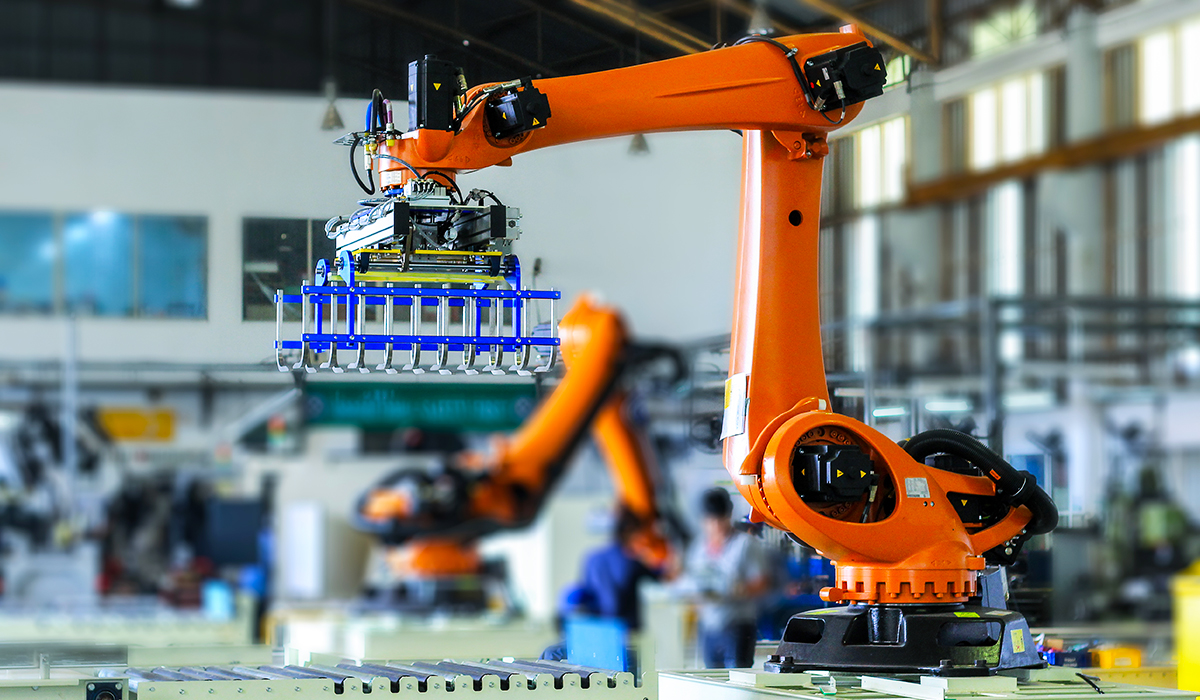

Custom Cable Assemblies for Specialised Sectors

For some sectors, like aerospace and defence , custom cable assemblies are necessary to meet compliance standards. In others, going custom might simply help deliver an improved or more robust performance.

Similarly, protecting your cables against electromagnetic interference (EMI) might be necessary to preserve signal integrity and support the proper performance of your electronics.

In sectors such as medical and life sciences , meeting regulatory standards and delivering uninterrupted signal and power transmission is vital. Bespoke cable assemblies can help ensure the function of medical electronics.

Likewise, the tough demands of the industrial sector often necessitate reinforced cabling that can deal with shock and vibration.

No matter your needs, we can work with you to deliver winning electronics solutions.

Custom Cable Assemblies

Whether you’re looking to improve on an established product or bring something new to market, we’re here to help design and manufacture exactly what you need

The earlier you involve us in your design process, the more impact we can have upon your product, whether that’s from a cost, lead time or performance perspective. We are also proud to provide prototypes quickly and easily, so that you can expedite your product’s route to market.

Find out more about our design and engineering support

Contact us today to find out more about the options available to you, or head over to our online Resources section for more helpful information.