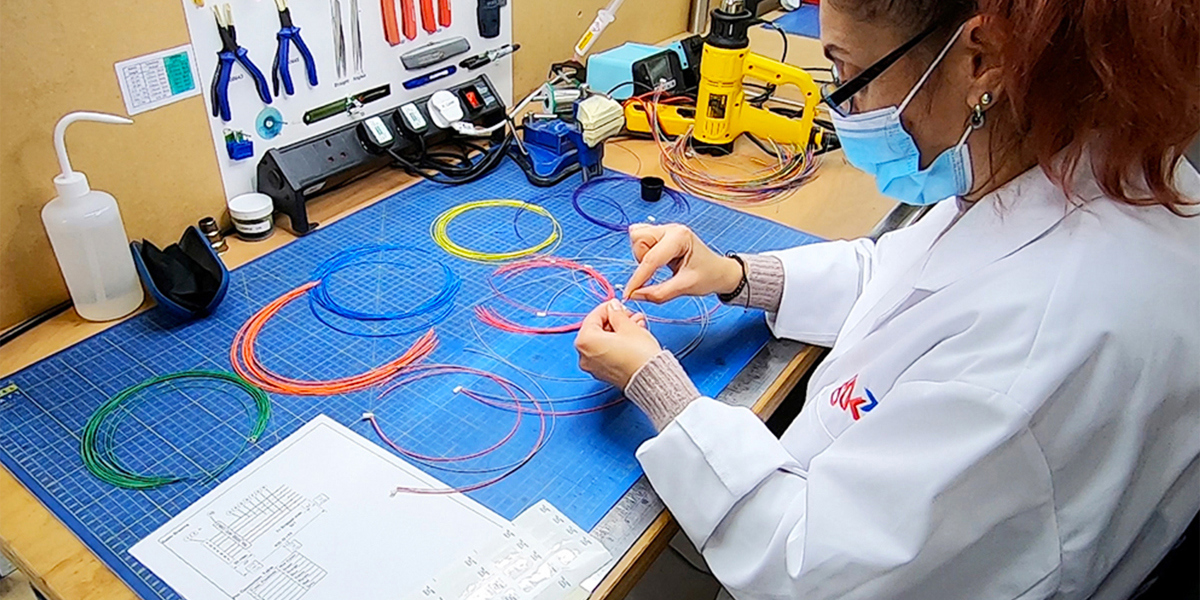

Tailor made Cable Assemblies

February 23, 2017 / Press Release , Cable Assemblies

It’s a given that all customers want to purchase high quality cable assemblies at a competitive price

However, if an OEM doesn’t have cable assembly manufacturing or sourcing experience, sometimes it can be overwhelming and time consuming.

GTK can take away the pain of this problem. With manufacturing facilities and partners across the globe, it can analyse the best technical and commercial options for its customers to work out the most suitable build model for each individual requirement. GTK has manufacturing facilities in the UK and Romania, and long-standing partnerships with manufacturing affiliates in the Far East. This global manufacturing footprint allows it to determine the most cost-effective way to deliver custom cable assemblies to customers anywhere in the world.

Chas Shale, business manager for cable assemblies at GTK, said, “There are several factors we need to take into consideration when we are quoting companies for custom cable assemblies, and the more information they can provide us with, the better the solution we can offer them. Volume is one consideration; lead-time is another. Are there any special approvals that need to be met? Where is the final delivery destination for the finished cable assembly? All of these elements and more will have a bearing on the manufacturing location or build model we select.”

GTK has operated manufacturing facilities in the UK and Far East for many years, and has recently opened a manufacturing facility in Romania, which expands its capabilities and provides a mainland European presence. Chas commented, “We had been planning the Romanian factory for some time before the referendum, but with the advent of the Brexit vote, we feel we made a sound decision as we now have a manufacturing facility in the EU. This puts us in a strong position to meet European customers’ needs in the future. The output from Romania is expanding dramatically and we are already exceeding our forecasted revenues from this plant. The addition of a third manufacturing location allows us to be more agile in our pricing and manufacturing, all of which is built into our own internal cost-modelling system. This helps us to determine what the most suitable options are for the customer, dependent on their priorities, and provide them with the best all-round solution in terms of product and price.”