Industrial

Building Automation

Electronics manufacturers in the building automation sub-sector face a number of challenges, such as the integration of various systems, ensuring energy efficiency and maintaining reliable operation in dynamic environments.

This complexity is complicated further by the need to enhance comfort, security and efficiency in buildings, while simultaneously delivering a user-friendly experience - this is where we come in.

Our expertise in engineering and design helps tackle these challenges by developing innovative solutions that improve system integration and energy management.

Our custom cable assembly capabilities and bespoke industrial displays enhance the reliability and efficiency of building automation systems, while our collaborative approach to working with customers ensures our products meet safety standards and deliver cost-effective solutions.

Our industrial displays can also be specified in a range of aspect ratios and form factors, to deliver your intended look, feel and usability.

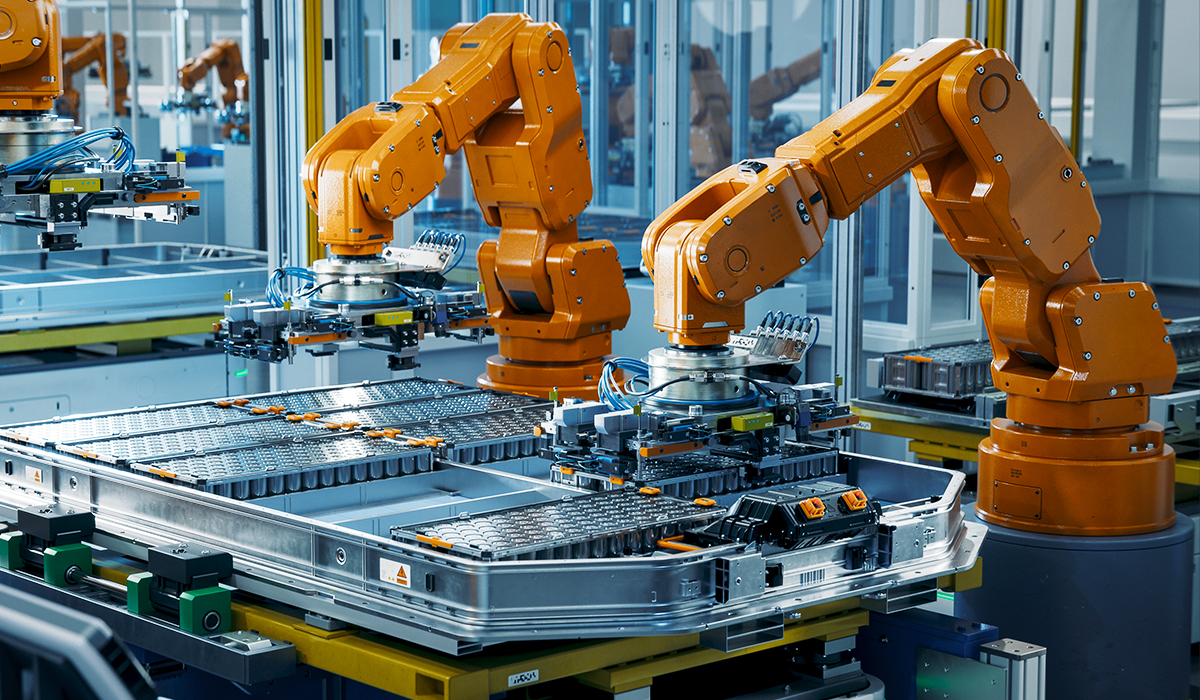

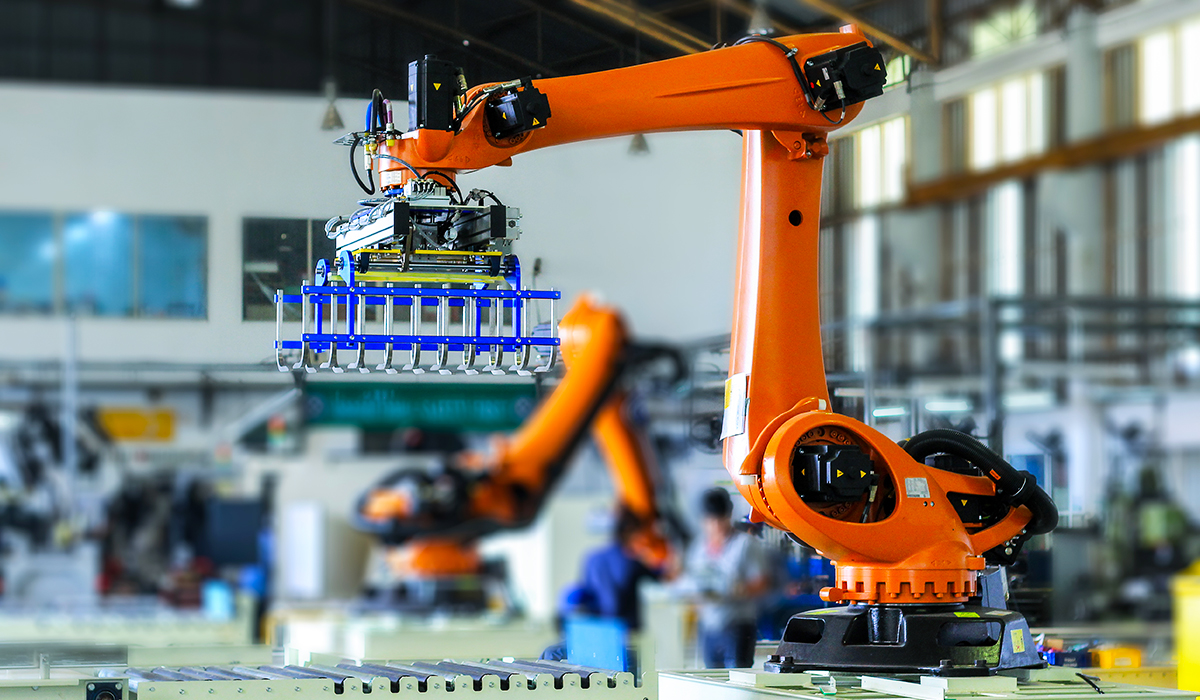

Factory Automation and Robotics

Electronics for use in factories and high-intensity production environments must deliver reliable, efficient performance in a range of harsh environments, operating seamlessly to ensure productivity, safety and cost-effectiveness.

With factory automation increasingly becoming the norm, companies operating in this space need to trust in the hard-wearing build and long-term reliability of their products.

Our engineering capabilities and resources enable us to support the development of high-performance factory automation systems. Plus, our expertise in designing and manufacturing custom cable assemblies ensures that factory automation systems operate efficiently and safely.

We collaborate closely with our customers to develop durable and reliable electronics components for a diverse number of industrial applications, with solutions ranging from flexible cable harnesses and customised connectors to overmoulding or waterproofing cable assemblies for maximum protection against shock, vibration and fluid ingress.

In terms of industrial displays, we can deliver cover lenses for extended protection, touchscreen capabilities for direct user-input, supply displays with longer-life backlights, or specify extended operating temperatures for high- or low-temperature production environments.

Industrial Lighting

The industrial lighting sector is continually evolving, driven by the need for energy-efficient and sustainable lighting solutions that comply with regulatory standards.

Companies must navigate technological advancements and ensure their lighting systems are both effective and compliant.

GTK’s extensive knowledge and engineering capabilities support the industrial lighting sector in developing solutions that are both efficient and sustainable.

We understand the importance of reducing energy consumption without compromising performance, working tirelessly to create custom electronic components for lighting systems that meet this goal.

Our product resources and engineering expertise ensure you stay ahead of technological advancements, offering cutting-edge support for lighting solutions that comply with the highest standards.

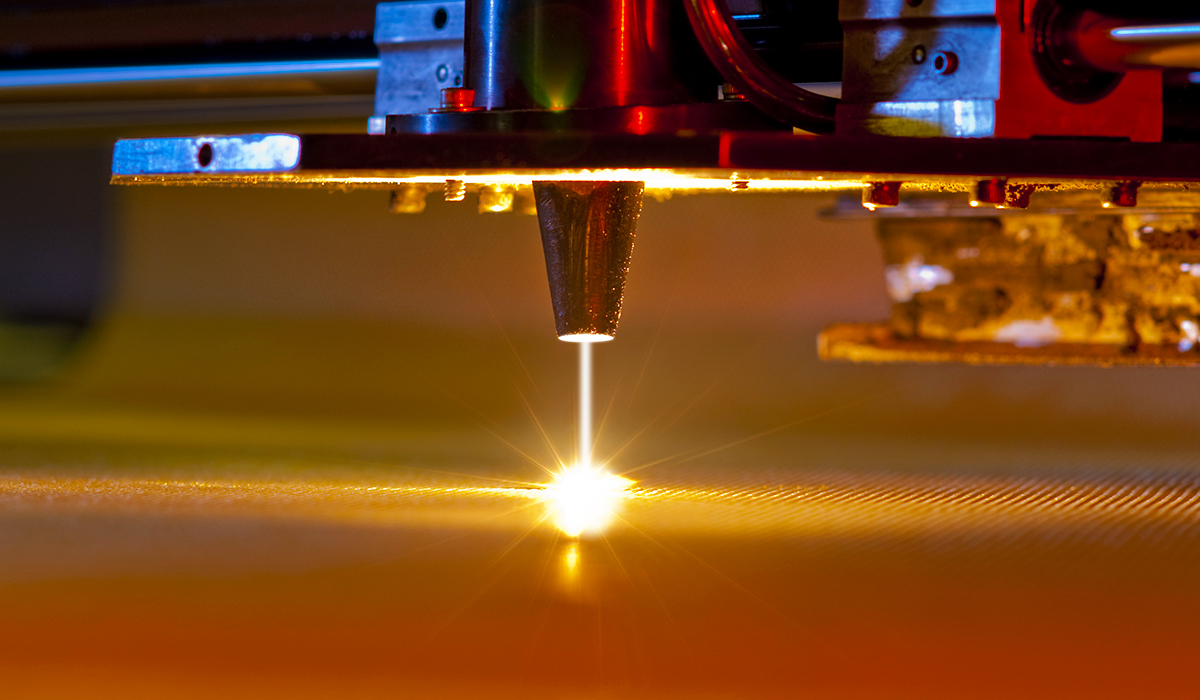

Lasers and Microscopy

Achieving high precision and accuracy while managing complex technical requirements are key for laser and microscopy applications.

Ensuring optimal performance and reliability when it comes to these demanding applications is crucial for the success of this kind of technology in industrial settings.

Our proficiency in this field enables us to address these challenges effectively, providing tailored solutions that enhance the precision and accuracy of laser and microscopy systems.

By leveraging our engineering expertise to deliver custom components built for purpose, we ensure optimal equipment performance, even in the most demanding environments.

We can also support with the delivery of innovative, user-friendly interfaces for industrial lasers and microscopes, using industrial touchscreen displays to operate these electronics safely and accurately, and embedded systems and software to run them.

Application story

Application story

Find out how GTK re-worked the cable assemblies for an electron microscope into a single, easy-to-install umbilical loom, complete with its own protective sheathing.

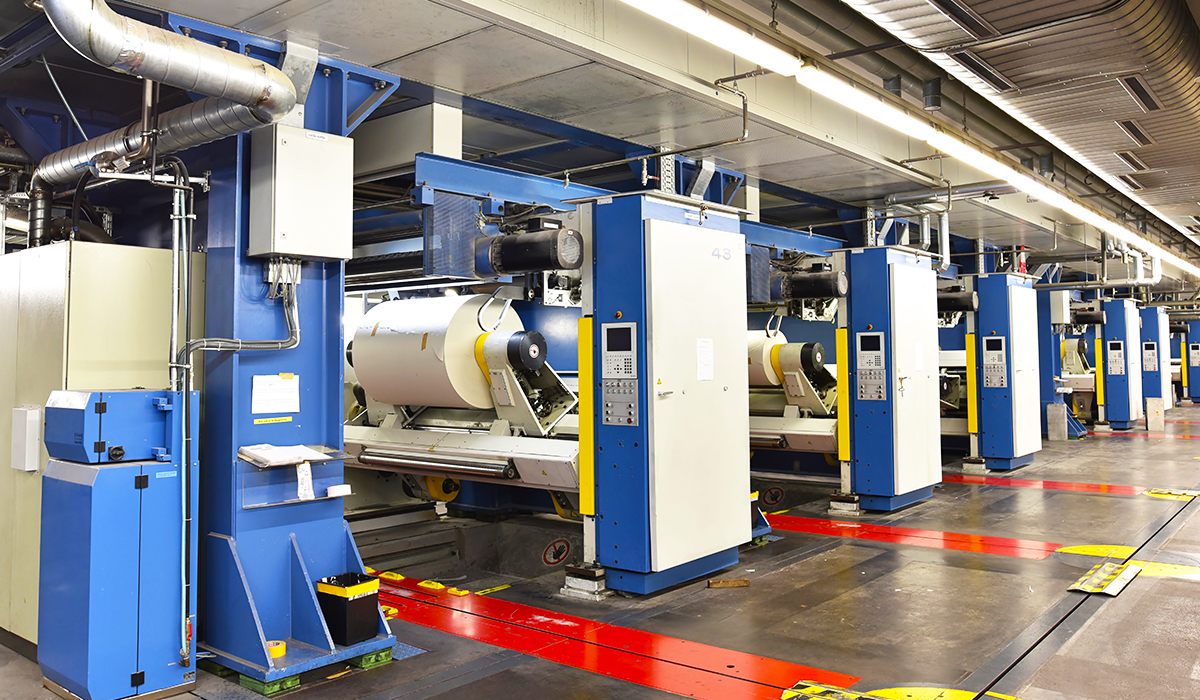

Industrial Printing

We are aware of the challenges in the industrial printing sub-sector, including ensuring the reliability and efficiency of electronic components in printing machinery.

Industrial printers operate in demanding environments, requiring robust designs that ensure consistent performance and high-quality output.

Our experience in designing and producing reliable electronic components helps tackle these challenges, providing solutions that enhance the performance and efficiency of industrial printing systems.

Specialised industrial wire harnesses are often required, and we work closely with our customers to develop bespoke solutions that ensure printing machinery operates efficiently and reliably.

Our ability to manufacture overmoulded and waterproof cable assemblies ensures your applications perform reliably, even in the challenging environment of industrial printing operations.

Application Story

Application Story

Find out how we developed a custom overmould for an industrial printing company, to protect their cables during the printer cleaning process.

Motion and Drives

Ensuring the reliability and efficiency of electronic components that must endure repeated use and strain is one of the main challenges of motion and drive applications.

These systems must operate seamlessly to ensure precise control, energy efficiency and safety across various industrial applications.

These can range from custom wire harnesses that are formed to accommodate the requirements of moving parts, to flexible board-to-board jumpers that deliver reliable connectivity, even under intense vibration and repetitive movement.

Our expertise in engineering and design enables us to develop innovative solutions that address these challenges. By focusing on reliable performance and energy efficiency, we help improve the accuracy and effectiveness of motion control systems.

Our custom components are designed to integrate seamlessly with existing infrastructure, ensuring smooth and efficient operations.

We work closely with our customers to develop tailored solutions that meet specific motion control requirements, contributing to the overall success of their operations.

Energy

Maintaining reliability, safety, and efficiency in industrial energy systems is essential as the sector transitions toward renewable integration, decentralised grids, and smarter control technologies.

From generation and storage to power conversion and distribution, every connection must perform under demanding electrical loads, temperature extremes, and harsh environments. Robust cable assemblies, high-current connectors, and control electronics all play a crucial role in ensuring consistent, safe operation.

Our extensive experience in manufacturing custom cable assemblies, branching wire harnesses, and control PCBAs, as well as supporting the latest Volex power cords, enables us to deliver solutions that meet the exacting standards of industrial energy applications.

By combining UK-based engineering support with global manufacturing capability, we help customers achieve improved reliability, efficiency, and long-term resilience across their energy systems.

Whether developing battery storage systems, renewable generation controls, or distribution infrastructure, GTK’s tailored electronic solutions provide the durability and performance needed to power the industry forward.

Our Certifications

In addition to having ISO 9001 and ISO 14001 approvals, our UK manufacturing facility is approved under the UL Wiring Harness Traceability programme. This means we offer complete traceability on all of the components used in the manufacture of wiring harnesses and defence cable assemblies.

This level of traceability gives our customers the added reassurance that the right components have been used and that their supply chain can be traced. We operate a cell manufacturing process, which results in highly efficient production and high-quality products, and all inspection is in accordance with the IPC 620 standard.

GTK also holds a number of other accreditations that demonstrate our best practices in a several different areas. One such certification, Cyber Essentials, highlights our focus on cybersecurity and data management, ensuring that we safely handle our customers’ sensitive information. We also hold ISO 45001 approval, illustrating our commitment to embedding robust occupational health and safety practices across our operations.