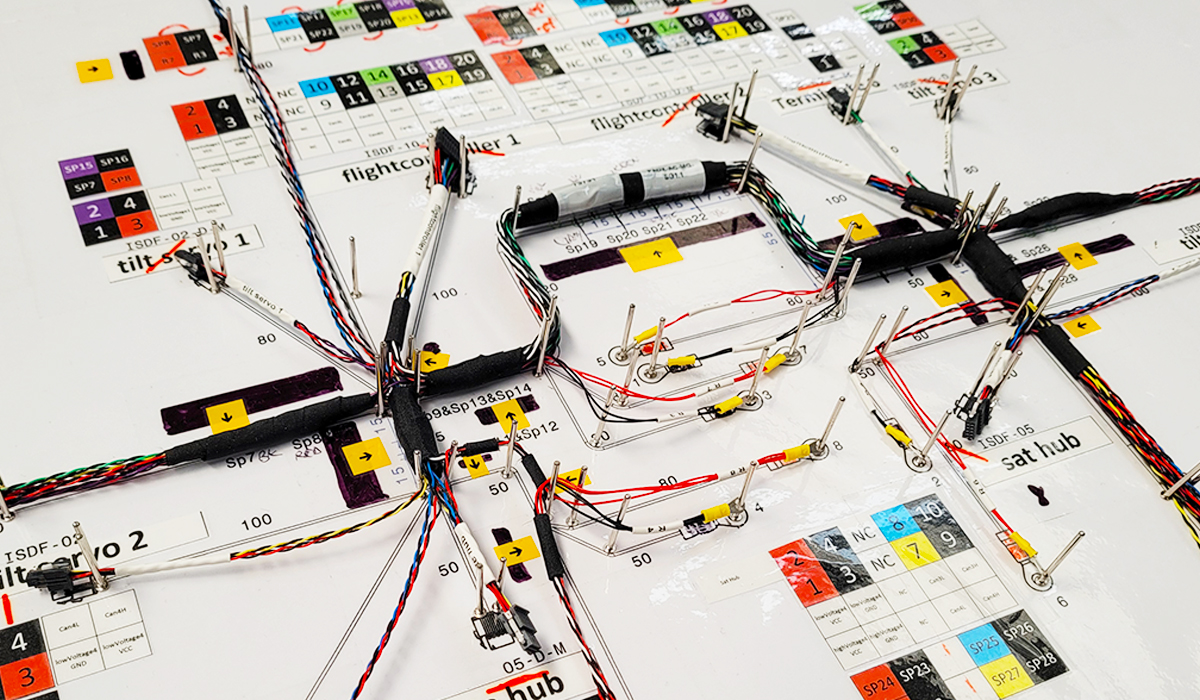

Wiring Harnesses

Part of our overall cable assembly offering, wire harnesses offer flexibility and cost savings, allowing you to combine various wire functions into a single harness.

Perfectly suited for internal use in your electronics devices, wiring harnesses deliver reliable transmission of multiple functions in a single loom.

Contact us early in your design process to find out how wiring harnesses could make your product build more efficient.

What is a Wiring Harness?

Also known as a loom or a cable loom, a wiring harness refers to a bundled assembly of cables, designed to safely and efficiently transmit power and signals within a larger system.

The key difference between a wiring harness and a regular cable assembly is that the latter will use a single (often multi-core) cable contained in an outer sheath that provides additional protection for external use.

In contrast, the wires in a wiring harness are jacketless, and instead are bundled and kept together using durable materials like cable ties, electrical tape or lacing.

In this way, wiring harnesses can be designed and formed to create branching paths leading to specific connectors.

What is a Cable Harness?

The term cable harness is often used interchangeably with wire harness, although there are some slight technical distinctions, which stem from the difference between wires and cables.

Cables often comprise multiple wires, so a cable harness might be more complex and comprise multiple cables, each containing multiple wires.

Benefits of Wiring Harnesses

Using wire harnesses in your product build offers a range of commercial, design and cost-saving benefits.

Simplifying your product build

Using a wire harness combines and organises multiple electrical components to allow simpler internal routing.

Space optimisation

Combining into a wire harness assembly means more efficient use of the space within your device, enabling new design possibilities.

Cost savings

Wire harnesses mean simpler installation and minimal waste, delivering cost savings per unit that boost your bottom line.

Security and stability

A well-designed harness will protect against environmental factors like heat, moisture and vibration, enhancing the durability and reliability of your final product.

Wiring Harness Applications

Wiring harnesses have a huge range of applications across a number of specialised sectors. While primarily used internally, this doesn’t mean that they aren’t durable – you can find wire harnesses in a huge range of places.

Aerospace: In aircrafts and spacecrafts, wire harnesses are critical for performance and safety, providing avionics, power distribution and more.

Defence: Wire harnesses conforming to mil-spec compliance standards are used for many applications in military electronics.

Medical devices: Wire harnesses are used to provide a range of functions in precise medical devices, including diagnostic equipment and more.

Consumer electronics: Wiring harnesses are used in many home appliances, like washing machines, computers, games consoles and more.

Industrial machinery: Wire harnesses or cable looms are used to power and control complex heavy industrial machinery.

Instrumentation and measurement: Highly accurate instrumentation and measurement devices utilise wire harnesses to maintain signal integrity.

Transport: Wire harnesses are used extensively in cars and other forms of transport, combining multiple functions safely and efficiently.

Why Choose GTK for Wiring Harness Applications?

For over 35 years we’ve provided customised manufacturing, engineering and design services for electronics OEMs, establishing GTK as a leading wire harness manufacturer globally.

With manufacturing locations in the UK, Europe and the Far East, we’re capable of meeting any order volume with any level of customisation, slashing lead times to help expedite your product’s route to market.

When you involve us early in your product design process, we’ll work with you to optimise your product design for manufacture, cutting build costs and specifying reliably available components under our core material strategy.

Get in touch today to find out how we can help.