Test & Measurement

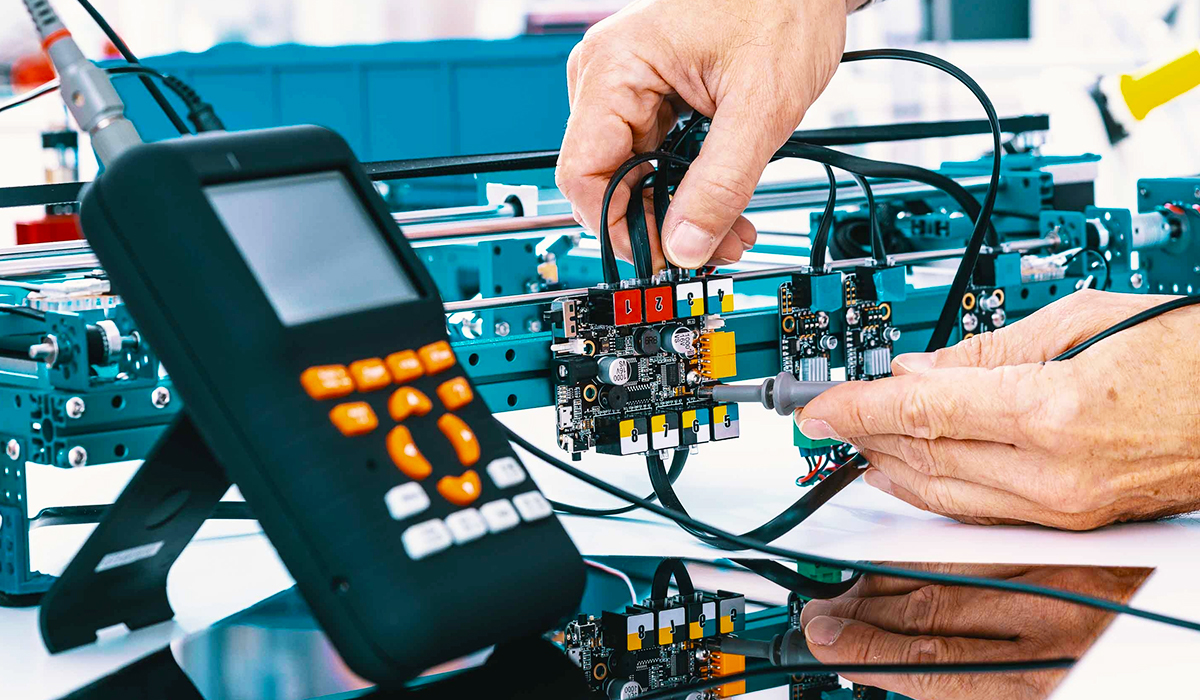

Metering

Metering applications require electronics that can deliver reliable, repeatable readings over long product lifecycles.

Accuracy, stability, and immunity to environmental and electrical interference are critical, as meters often need to operate continuously and be field-deployed in harsh or unpredictable environments.

Meeting international standards and maintaining cost efficiency further complicate the picture.

We recognise that meter manufacturers face strict calibration and certification requirements, and their devices must often function in the field for a decade or more with minimal maintenance.

This places heavy demands on the durability of displays, connectors and cable harnesses, as well as the stability of embedded systems .

At GTK, our engineering and prototyping services help customers design robust solutions that balance precision with resilience. With production capabilities in the UK, Romania and the Far East, we offer flexibility in scale and cost while ensuring consistent quality.

This combination enables our customers to launch metering products that meet stringent accuracy standards and stand the test of time.

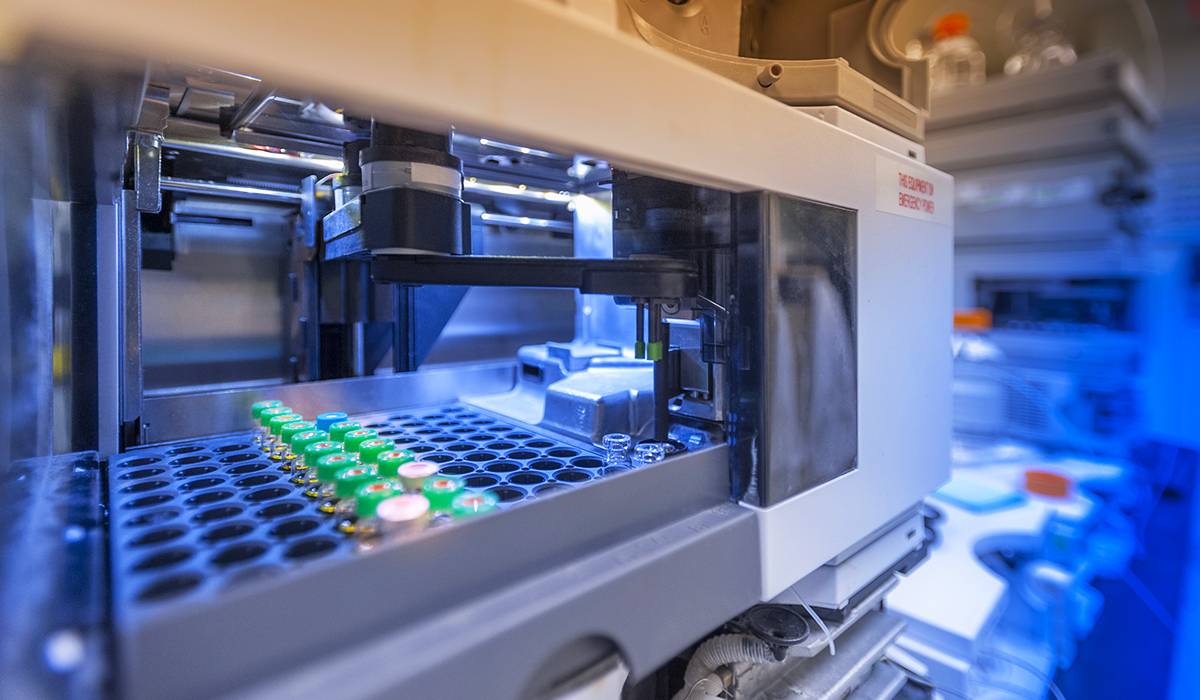

Lab Equipment

Laboratory instrumentation must combine exceptional accuracy with user-friendly interfaces, all while meeting safety and compliance requirements.

Devices are becoming more sophisticated and connected, with increasing demands for compact designs, higher performance, and integration with digital platforms for data capture and analysis.

Lab environments place unique requirements on electronics, including the need for precision measurement, long-life displays, and reliable power and signal connectivity. Equipment must also be flexible enough to evolve with advancing technologies, without sacrificing performance or compliance.

At GTK, we provide technical expertise that helps lab equipment manufacturers refine their designs for usability, accuracy and reliability. Our ability to rapidly prototype cable assemblies allows developers to shorten development cycles and validate design concepts early.

By synergising our global manufacturing facilities, we support both specialised low-volume builds and higher-volume production with consistent quality standards, helping our customers to deliver advanced laboratory equipment on time and with confidence.

Field Data Logging

Field test equipment and data loggers must operate in tough, real-world conditions where dust, moisture, vibration and temperature extremes are constant challenges.

At the same time, users expect portability, compactness, long battery life and wireless connectivity, all while maintaining accuracy and reliability.

Designing electronics for outdoor or industrial deployment means balancing ruggedisation with ease of use. Devices need robust connectors, durable enclosures, and displays that remain legible in varying light conditions, all without compromising measurement performance.

GTK works closely with customers to engineer tailored solutions that withstand environmental stresses and ensure long-term dependability. Our global supply chain enables cost-effective production of ruggedised electronics, while our engineering support helps optimise designs for compactness, efficiency and usability.

With our FastTrack prototyping service, customers can validate rugged field equipment quickly, helping to reduce development risk and accelerate time-to-market.

Application Story

Application Story

Find out how GTK redesigned a customer's industrial data logger to use a besoke overmoulded connector that reduced their cost and improved reliability.

Weighing

Weighing applications require consistent accuracy and repeatability across varied load ranges and conditions. Equipment often needs to interface with wider systems, from industrial process controls to retail point-of-sale, meaning the electronics must be both precise and adaptable.

Long lifecycles and cost-sensitive production further increase the pressure on OEMs.

Weighing systems demand reliable electronics that remain stable over time, even when exposed to mechanical stress, vibration or environmental factors. Displays must be durable yet user-friendly, and connectivity solutions must allow seamless integration with other equipment and networks.

At GTK, we support weighing OEMs with engineering expertise to design solutions that deliver accuracy, resilience and cost efficiency. Our ability to provide tailored assemblies, coupled with global manufacturing in the UK, Romania and Far East, ensures flexibility in meeting volume and cost requirements.

By partnering with us, customers can focus on optimising performance, knowing that the underlying electronics will provide the long-term stability and quality that their applications demand.

Our Certifications

In addition to having ISO 9001 and ISO 14001 approvals, our UK manufacturing facility is approved under the UL Wiring Harness Traceability programme. This means we offer complete traceability on all of the components used in the manufacture of wiring harnesses and defence cable assemblies.

This level of traceability gives our customers the added reassurance that the right components have been used and that their supply chain can be traced. We operate a cell manufacturing process, which results in highly efficient production and high-quality products, and all inspection is in accordance with the IPC 620 standard.

GTK also holds a number of other accreditations that demonstrate our best practices in a several different areas. One such certification, Cyber Essentials, highlights our focus on cybersecurity and data management, ensuring that we safely handle our customers’ sensitive information. We also hold ISO 45001 approval, illustrating our commitment to embedding robust occupational health and safety practices across our operations.