Transport

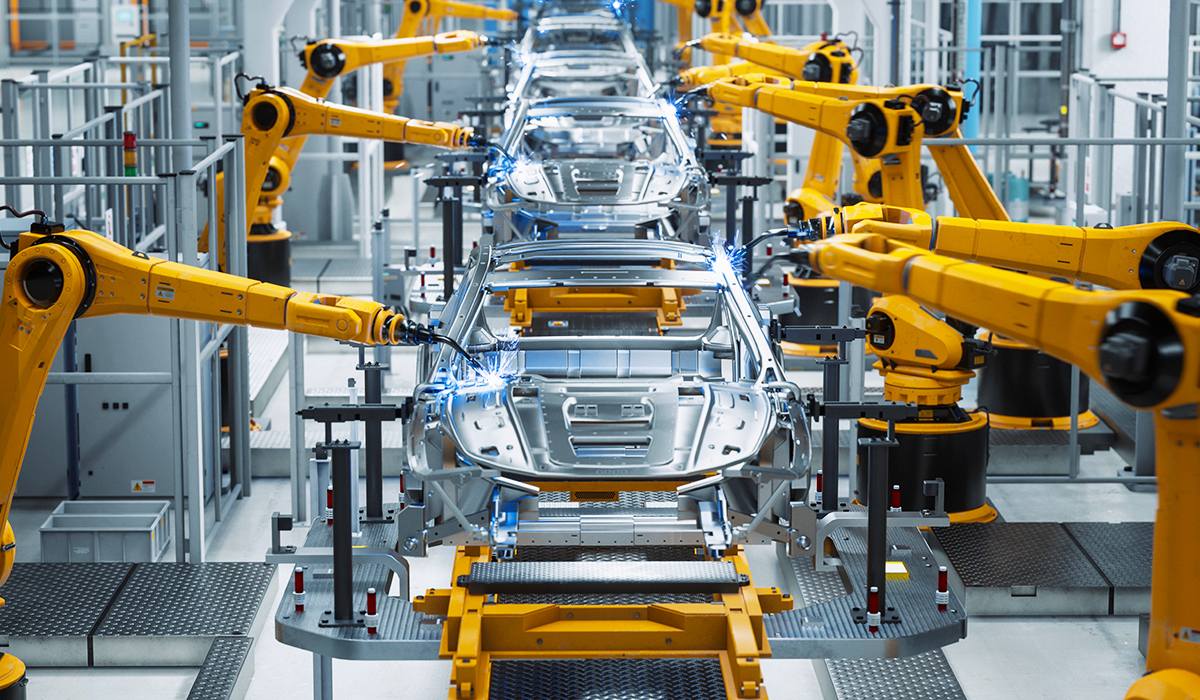

Automotive

The automotive sector presents a host of technical and regulatory challenges. Electronic designs must endure extreme temperatures, vibration, electromagnetic interference and exposure to fluids, all whilst meeting the stringent quality standards of TS16949.

The push towards smarter, more connected vehicles also calls for highly reliable, miniaturised electronics with high-speed data support and a long service life.

Automotive electronics solutions must meet demanding durability requirements, ensuring reliability under constant temperature changes, road vibration and chemical exposure. There is intense pressure to minimise lead times while maintaining cost efficiency, as well as to meet manufacturer standards and certifications.

Our experience producing overmoulded automotive cable assemblies and custom wire harnesses, robust connectors (including I/O and RF types), and custom displays helps address these challenges.

Drawing on our UK-based design and engineering support, combined with manufacturing in Romania and partner facilities in the Far East, we provide tailored, high-quality solutions with efficient turnaround.

Our FastTrack prototyping service is particularly valuable for quickly approving concepts and reducing your time-to-market.

Electric Vehicles (EV)

Electric Vehicle (EV) applications introduce unique challenges, including high-voltage safety, thermal management, electromagnetic compatibility, power density and charging infrastructure compliance.

EV systems must be compact and rugged, with exceptional reliability under a wide range of operating conditions.

EV solutions call for a blend of safety, performance, and durability: connectors and cable assemblies that can withstand high voltage and thermal stress, internal sensors and displays that are resilient yet power efficient, and external charging interfaces that endure repeated use and exposure.

At GTK, we leverage our ability to supply Volex power and connectivity systems alongside our display and embedded capabilities (strengthened through the integration of Review Display Systems) to deliver secure and reliable electronics for EV applications.

We combine our UK-based engineering technical support with global manufacturing, ensuring certification compliance, quality control, and scalability, while our FastTrack prototyping helps accelerate new EV designs.

Rail

In the rail sector, electronics must tolerate sustained vibration, temperature extremes, strict safety standards and long product life cycles.

What’s more, new designs often need to integrate with legacy systems while supporting high-visibility displays and real-time data systems.

Rail electronics must be exceptionally robust, often with extended backlight life for displays and flawless performance over many years. Electronic assemblies and connectors must resist vibration and thermal shock while offering continued support and replacement availability.

Our experience in producing rugged displays (such as panels designed for extended use and long availability), and our custom connectors and cable assemblies built to withstand challenging operational environments, position GTK to assist OEMs in delivering reliability and longevity in their rail electronic applications.

Additionally, our global manufacturing footprint ensures both scalability and consistent quality.

Marine

Marine environments can be corrosive, moisture-rich and prone to shock and vibration.

Marine cable assemblies and connectors must be highly sealed, corrosion-resistant, and able to withstand salt spray, humidity, and temperature fluctuations.

Marine electronics must survive exposure to salt water, frequent vibration and wide temperature variations. Put simply, harshness is the norm. We respond by supplying connectors and cable assemblies with waterproofing, corrosion-resistant materials, and rugged overmoulds that resist ingress and wear.

Our engineering team draws on global expertise, from design to supply, backed by manufacturing across the UK, Romania and the Far East to ensure that marine electronics remain dependable, customisable, and delivered on time.

![]()

Commercial and Tracking

Electronics systems in commercial vehicles, such as tracking systems must be network-ready and able to handle varying power inputs.

Often, these systems will face demanding mobile environments, including constant vibration, exposure to the elements, communication reliability, compact form-factors, and tight cost constraints.

Commercial vehicles, fleet tracking systems and telematics demand compact, energy-efficient electronics that can survive intense physical stress and shifting operating conditions. They must usually include ruggedised connectors, assemblies resistant to dust, water or debris, and displays or embedded systems that relay real-time information reliably.

We help tackle these challenges with high-durability connectors ranging from standard I/O to high-frequency RF solutions, as well as bespoke cable assemblies, compact embedded systems and displays, all backed by our expert manufacturing support and rapid prototyping.

With quality assured through ISO and UL standards, as well as an agile supply chain across multiple manufacturing locations, we help streamline deployment of robust tracking electronics.

Off-Road

Off-road and agricultural vehicles operate in dust, mud, vibration, and temperature swings.

Their electronics systems must be sealed, shock-tolerant, and often highly customised, with extended support due to the long service life expected of heavy-duty machinery.

In agri-tech and off-road contexts, environments are extremely tough – exposure to dust, mud, impact and large temperature shifts are common for these devices that often remain in service for many years.

Off-road electronics must be particularly durable; bespoke cable assemblies, rugged connectors with overmoulding and custom embedded displays are essential.

GTK’s pairing of global manufacturing with UK engineering support enables us to offer tailored solutions with rapid development cycles, with consistent quality and extended lifecycle availability.

We understand the pressures of maintenance, uptime, and environmental resilience, and our solutions are built to help you meet these demands head-on.

Application story

Application story

Find out how GTK redesigned a customer's agri-tech cable assembly, delivering reduced costs and improved protection by synergising our global manufacturing.

Our Certifications

In addition to having ISO 9001 and ISO 14001 approvals, our UK manufacturing facility is approved under the UL Wiring Harness Traceability programme. This means we offer complete traceability on all of the components used in the manufacture of wiring harnesses and defence cable assemblies.

This level of traceability gives our customers the added reassurance that the right components have been used and that their supply chain can be traced. We operate a cell manufacturing process, which results in highly efficient production and high-quality products, and all inspection is in accordance with the IPC 620 standard.

GTK also holds a number of other accreditations that demonstrate our best practices in a several different areas. One such certification, Cyber Essentials, highlights our focus on cybersecurity and data management, ensuring that we safely handle our customers’ sensitive information. We also hold ISO 45001 approval, illustrating our commitment to embedding robust occupational health and safety practices across our operations.