Engineering Reliability: Designing Cable Assemblies that Endure the Harshest Conditions

October 21, 2025 / Blog , Cable Assemblies , Connectors , Embedded

In the world of critical systems, one often overlooked factor can make or break mission success: the cable assembly.

Whether for military platforms crossing deserts, industrial plants operating in corrosive atmospheres, or aerospace vehicles enduring extreme temperature swings, our engineering philosophy is simple but uncompromising: manufacture cable assemblies that last.

Facing the Elements: What "Harsh Conditions" Really Means

Harsh environments go far beyond mild vibration or temperature swings. Whether inside a train undercarriage, a factory control panel, or an aircraft fuselage, cable assemblies must withstand:

- Wide Temperature ranges, from deep cold to scorching heat

- Intense vibration, shock, and mechanical stress

- Moisture ingress, chemical exposure, salt spray, and dust

- Electromagnetic interference (EMI) and radio frequency (RF) noise

- High altitude or pressure differentials

- Cyclic fatigue over long service lives

Engineering cable assemblies to survive these challenges takes more than rugged materials, it requires design foresight, disciplined testing, and a reliable, traceable supply chain.

Design Philosophy & Key Techniques at GTK

1. Early Design Involvement & DFM

By engaging early with OEMs, our engineers influence routing, conductor sizing, insulation, and connector selection to ensure manufacturability, performance, and cost control.

2. Material Selection & Core Material Strategy

Our Core Material Strategy secures key cables, wires, connectors, crimps, and labels to maintain supply continuity, reduce lead times, and ensure consistent quality. Materials are selected for thermal stability, flexibility, and chemical resistance - critical for long-term reliability. Additionally, CMS crimps and connectors leverage existing calibrated tooling, enabling efficient and consistent production

3. Ruggedisation: Overmoulding, Shielding & Protection

Overmoulded assemblies enhance strain relief and environmental sealing. Cable shielding, whether foil, braid, or a foil-braid combination, preserves signal integrity in high-EMI or RF environments. Additional protective layers, such as external metal or nylon braids, sleeves, or conduits, can be applied over the cable jacket to improve ruggedness and resistance to abrasion and vibration.

4. Qualification, Testing & Traceability

Every assembly is fully tested and documented. Our approval under AS9100, as well as the UL Wiring Harness Traceability Program, ensures complete component traceability, while our ISO 9001, ISO 14001 and ISO 45001 certifications underpin our operational processes.

Applications Across Industries

GTK supplies mission-critical assemblies across sectors where reliability cannot fail:

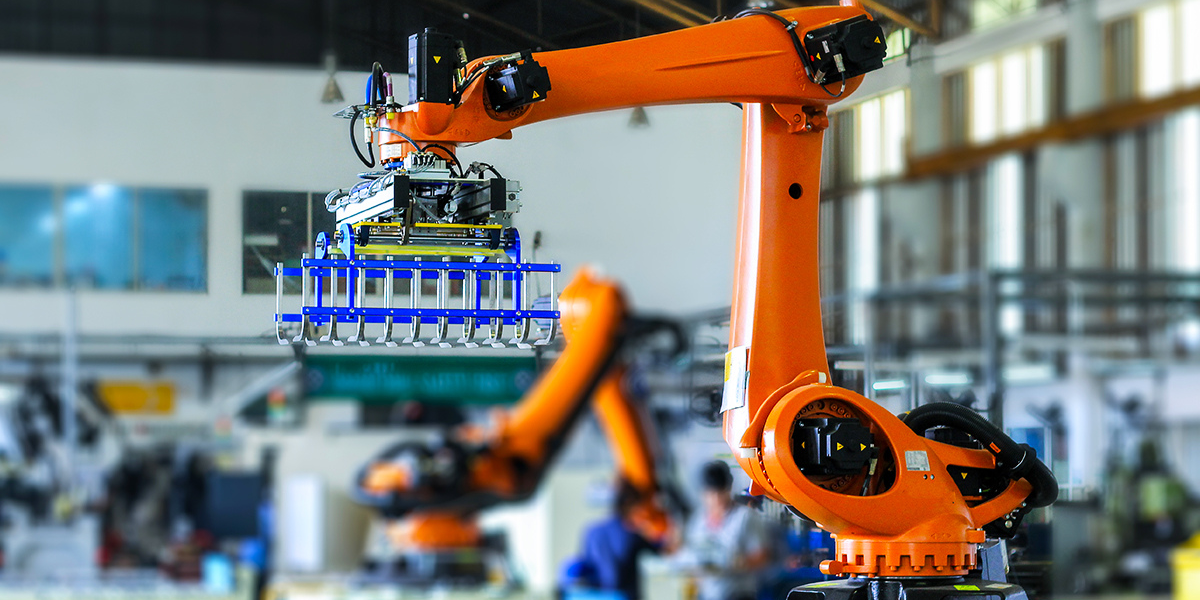

- Industrial automation: Flexible, chemical-resistant cabling for robotic arms, sensors, and control panels operating in high-temperature or oily environments.

- Transport and rail: Vibration-resistant harnesses with enhanced sealing and abrasion protection for rolling stock, signalling, and on-board electronics.

- Defence and aerospace: Lightweight, high-reliability assemblies for mission-critical platforms using MIL-spec connectors.

- Energy and environmental systems: moisture-sealed assemblies for renewable power, EV charging, and outdoor installations.

Why GTK?

GTK combines UK-based design and engineering with manufacturing in the UK, Romania, and the Far East - offering both flexibility and scale. Our collaborative approach spans from BOM review and prototyping to final qualification, ensuring each assembly performs throughout its service life.

In any system, the cable harness is the invisible backbone that must endure when everything else is tested. Through early-stage engineering, material discipline, ruggedisation, and verification, GTK manufactures assemblies built to survive the harshest conditions.