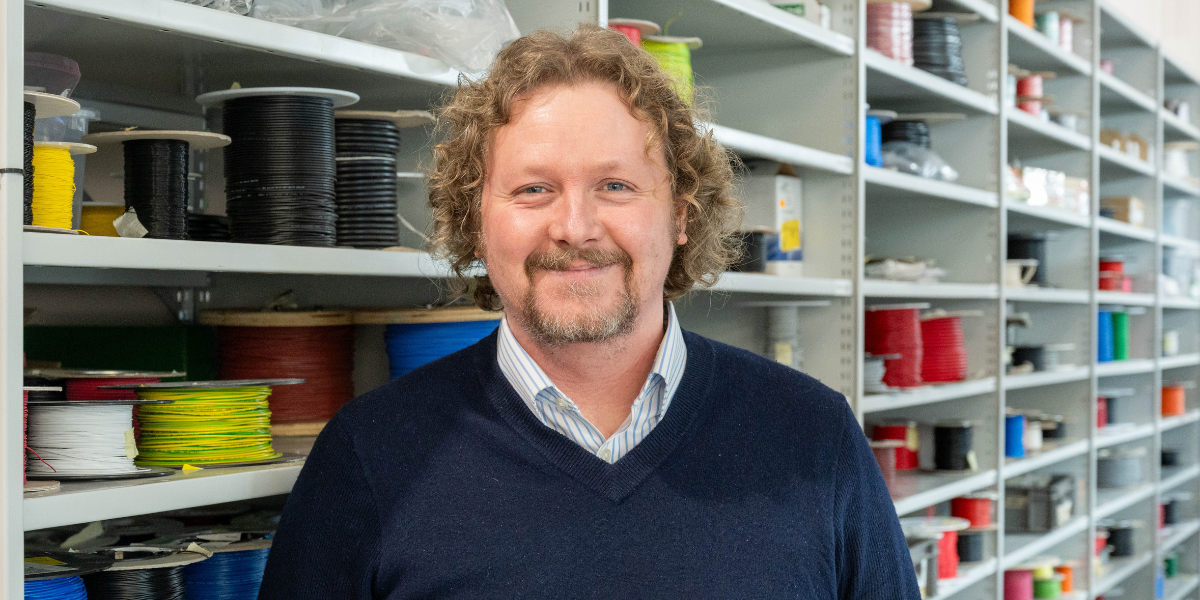

Meet Matt Eden, our Engineering Director driving innovation

December 1, 2025 / Blog , Interview

Get to know Matt Eden, Engineering Director at GTK, and find out more about his career journey to date, his day-to-day agenda and proudest moments working at the company.

Could you tell us a bit about your journey into the sector?

“I’ve always been really interested in technology. Problem-solving, creativity and trying to understand how things work have always come naturally to me, so engineering felt like the obvious direction.

“I began my career as an apprentice with a company that manufactured large-scale audio equipment for open air concert & festivals. It was the perfect introduction to the manufacturing industry - very hands-on, very practical, and it gave me exposure to everything from production and testing to quality assurance.

“After that, I moved to manufacturing AGL (Airfield Ground Lighting) products for airports. Where I progressed into technician and team-lead roles. Then I moved into positions that blended engineering with customer-facing responsibilities, including product development, NPI and production engineering. Eventually, all those experiences led me to GTK.

“I have been lucky enough to have three senior mentors during my career to date, they have been absolutely invaluable. They let me shadow them, encouraged me to ask questions, and helped me understand the full process from specification all the way through to installation & commissioning.”

Matt Eden, Engineering Director at GTK

How do those experiences shape what you’re doing at GTK today?

“Having spent time in both hands-on engineering and customer-facing positions, I've learned how important it is to see things from every angle, from design and production through to how the products are actually used. At GTK, that experience helps me focus on making our processes as efficient and reliable as possible, while also keeping innovation a priority.

“It's also influenced how I work with the team, encouraging collaboration, sharing my knowledge, and always looking for better ways to do things. Those earlier experiences definitely gave me the foundation to help drive that culture forward here.”

What’s been your proudest achievement in your role so far?

“One of the highlights so far has for sure been taking a leading role in setting up our Romanian factory. Going into a situation like that from the very beginning was so exciting – taking an empty building and specifying all the machinery, doing CAD for how we’re going to lay out the factory and all the benches, the pneumatics was amazing.

“I spent a lot of time flying to and from Romania – the whole thing was a huge opportunity for me and has really helped the business accommodate different order volumes with different requirements, compared to our UK manufacturing and in the Far East.“

What did that experience teach you that you’re applying to GTK’s next phase of improvement?

“It really showed me the importance of planning carefully but staying flexible when things change. Setting up a factory from scratch meant thinking about every little detail, but also being ready to adapt. I try to bring that approach to GTK now, whether it’s improving processes, supporting the team with new challenges, or finding effective ways to handle more complex orders.”

Could you point to any key challenges you’ve faced in your role so far?

“Being a contract manufacturer, the speed we work at can present some challenges. For example, for some businesses, the R&D phase of their NPI project can take up to four/five years and beyond. We’re condensing all of the NPI and manufacture into a six-to-eight-week turnaround time – and we’re doing over 40 NPIs a month.

“So, I’m always striving to make sure that we’re constantly improving our processes to become more efficient than ever. Thankfully, we’re a very data-driven company, and there’s plenty of insight to draw from.”

"I’m especially excited about the move towards automation and higher output in the UK. These developments will be key to helping us reach our ambitious growth targets, and they’ll really strengthen the way we operate day to day."

How has the engineering function at GTK evolved in the last few years?

“The engineering function at GTK has grown significantly. What started as a small, two-person team has developed into a department made up of two dedicated teams, one for upstream tackling costings and customer quotes and one for downstream working directly with our production operators on builds. We’re also working across two sites – the UK and Romania – and are supported by skilled technicians.”

How did you build your team at GTK?

“Over the years, our approach to building the team has evolved a lot. While experience is still valuable, we’ve really focused on bringing in young talent, both as apprentices and graduates, and giving them the support and mentorship I benefited from early on in my career. Right now, that means working closely with the three graduates in my team, helping them grow their skills and encouraging them to take ownership of projects.

“Looking forward, we’re focused on developing a team that’s ready for the future of engineering at GTK. That includes building expertise in automation, lean manufacturing, and new technologies, while making sure everyone has the skills to adapt as processes and customer needs evolve. It’s exciting to see the team taking on more responsibility and really driving innovation, and being able to guide that development makes it incredibly rewarding.”

How are you preparing your engineering team for the demands of future customer projects?

“A big part of our approach is making sure the engineers spend real time with customers. Giving the team direct exposure helps them understand requirements more clearly, see how our products are being used, and get a feel for the markets we’re working in. That insight means we can plan better, design smarter, and be ready for what future projects will demand.”

How do you see the UK and Romanian sites working together as the business continues to scale?

”Our UK and Romanian teams will continue to operate as a single global team, using the same scheduling tools, ERP system, and maintaining the same accreditations ensures consistency and alignment across both sites.”

How does GTK stay competitive as lead times shrink and complexity increases?

“For us, staying competitive is all about keeping our lead times strong as the business grows. We’re focused on strengthening our processes and resources to handle the increasing complexity, so we can keep delivering on time, reliably, and without ever compromising on quality.”

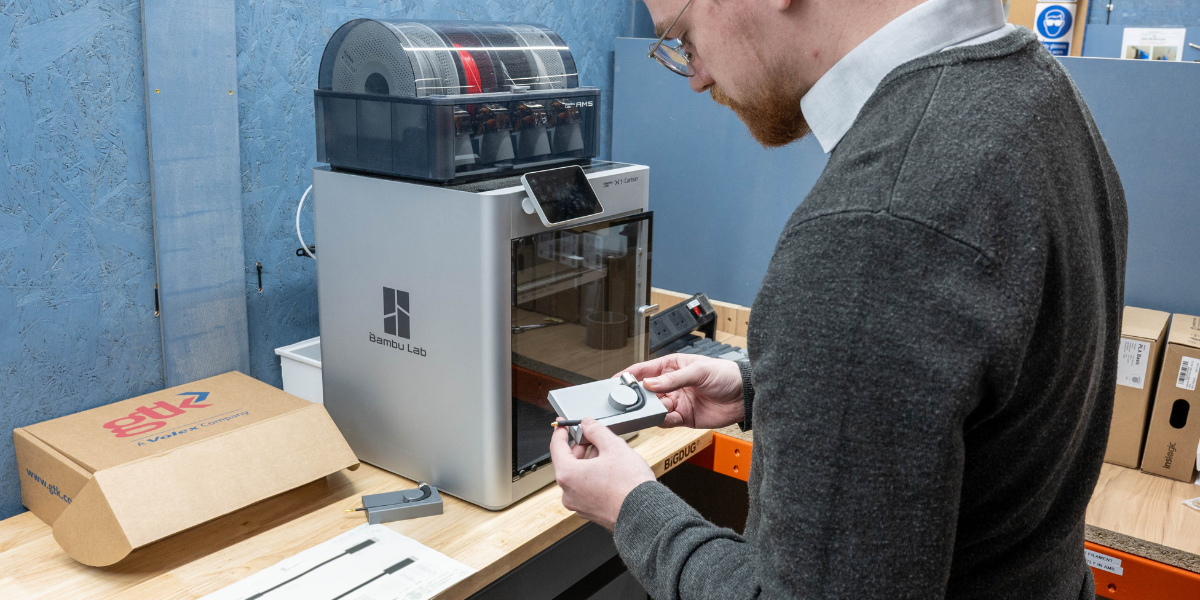

GTK's graduate engineers, mentored by Matt, bring a fresh approach to the company.

Which engineering innovations or tools are you most excited for GTK to adopt?

“I’m especially excited about the move towards automation and higher output in the UK. These developments will be key to helping us reach our ambitious growth targets, and they’ll really strengthen the way we operate day to day. It’s a big step forward for the department and for the business as a whole.”

What exciting applications or technologies do you see GTK supporting more of in the coming years?

“Lately, we’ve seen more inquiries in areas like automation, healthcare, and clean energy. People are looking for electronics that are smarter, more reliable, and easier to integrate, whether that’s in surgical robots, portable medical gadgets, or even electric vehicles.

“GTK’s always been good at adapting and we like a challenge. As new technologies come along, we’re focused on finding practical ways to support them and help our customers turn great ideas into reality.”

Are there any trends in electronics or manufacturing that you think will shape the work GTK does in the coming years?

“I’d say the biggest trend is being customer-led. The work we do has always been driven by customer needs, and that focus will continue to guide how we design, manufacture, and deliver our products in the years ahead.”

What are your priorities for advancing GTK’s engineering capabilities over the next 12–24 months?

“A key focus for the next couple of years is supporting our five-year plan for deeper market penetration in both the UK and Romania. That means making sure our engineering capabilities grow in the right areas, so we can meet demand, stay competitive, and continue delivering the level of service our customers expect.”

What are you most excited about for GTK over the next few years?

“For me, it’s definitely the variety in the work we do. We get to serve a wide range of markets, and almost every project is completely custom - no two jobs are ever the same. That keeps things interesting and constantly pushes us to innovate and adapt."