Meet Lucia, our Production Planner aligning teams and timelines

February 5, 2026 / Blog , Interview

With two decades in manufacturing and a passion for practical problem-solving, GTK Production Planner, Lucia Goncalves, talks to us about her role in keeping schedules stable, customers satisfied and teams aligned.

Tell us about your career journey and what brought you to GTK?

“I have over 20 years of experience in electronics manufacturing across the UK and Portugal. I began my career as a warehouse operator and quickly progressed into a team leader role. Later, becoming an SAP Key User expanded my technical and process knowledge, eventually opening the door to my transition into production planning.

“Throughout my career, I’ve built a strong understanding of how operations, planning, logistics and production interact, which allows me to make informed decisions and support cross-functional collaboration.

“GTK appealed to me because cable assembly manufacturing presented a new challenge, an opportunity to step outside my comfort zone. The role offered full ownership of end-to-end production planning, which aligned perfectly with both my experience and my ambition to continue progressing in manufacturing leadership.”

Lucia Goncalves, Production Planner at GTK

What does your role as a Production Planner involve on a day-to-day basis?

“My role focuses on ensuring production runs smoothly, efficiently and in line with customer expectations. I review the schedule, check new orders and adjust priorities based on capacity and material availability.

“I stay closely aligned with the shop floor to monitor progress and resolve issues quickly. I also work with the Purchasing, Sales, Engineering and Quality departments to keep everyone updated on risks and priorities. Ultimately, my focus is on keeping the plan realistic, efficient and on time."

Which parts of your role do you find most rewarding or enjoyable?

“For me, the most fun part of being a Production Planner is the problem-solving. Every day is different, and there’s always a new challenge, whether it’s a material shortage, a capacity constraint or a customer pulling in an order.

“I enjoy analysing the situation, finding solutions quickly and keeping everything running smoothly. I also really enjoy the coordination aspect. You get to work with every department, which means the role is dynamic and never boring.”

How has your previous experience shaped the way you approach production planning and scheduling?

“My experience has given me a full understanding of production from the ground up. Working in the warehouse taught me the importance of materials and accuracy, being a team leader showed me how the shop floor really works and my SAP Key User role taught me how data drives good planning.

“Together, this helps me create realistic schedules, spot risks early and communicate effectively across departments.”

From your perspective, what truly sets GTK's production processes apart from other manufacturers?

“GTK is a unique combination of flexibility, multi-site collaboration and a customer-first mindset. Our two sites, in the UK and Romania, allow us to optimise capacity and lead times.

“We’re able to respond quickly to customer changes, while maintaining strong on-time delivery performance. The level of cross-team communication is also a real strength, as everyone is involved in delivering a reliable plan.”

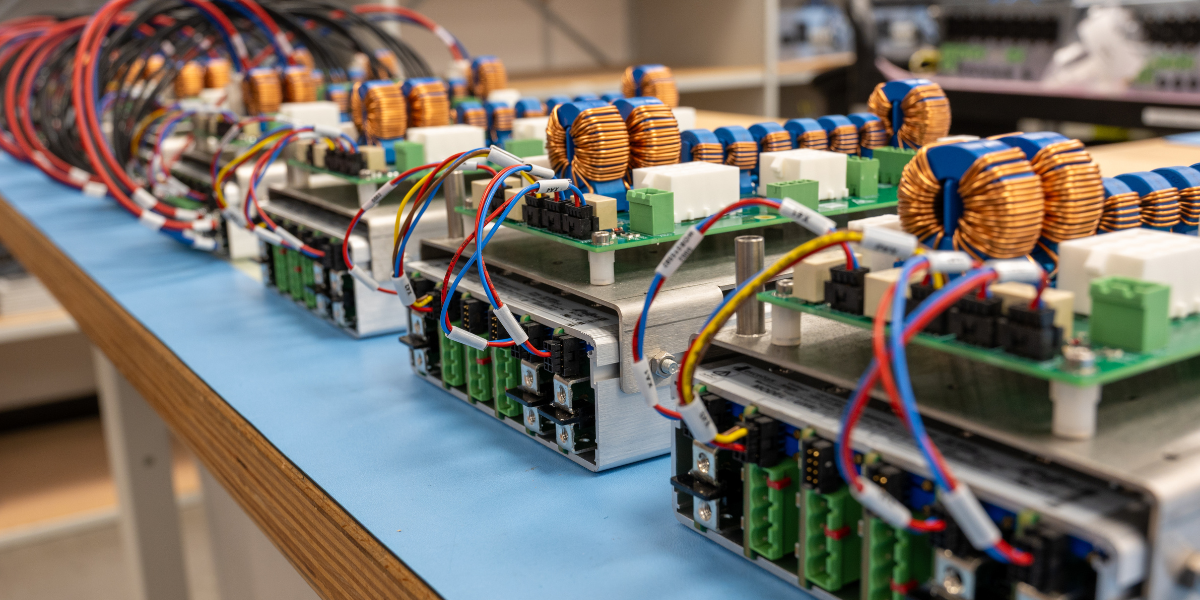

A custom Box Build solution, manufactured in GTK's purpose-built ESD room

Can you share an example of a challenging scheduling scenario and how you resolved it?

“When I joined GTK, scheduling was done using forward planning, which caused constant rescheduling. When several urgent orders were pulled in at once, capacity became overloaded, potentially putting on-time delivery at risk.

“I introduced backward planning: the process of scheduling from the customer delivery date instead of from the day. This change stabilised the plan, aligned capacity and materials, and protected delivery dates without unnecessary overtime or disruption.”

Have you noticed any recent changes in customer demand or production requirements?

“Yes, demand has changed a lot. Customers now expect shorter lead times, more flexibility and more frequent changes to forecasts.

“To keep up, I work with tighter daily planning cycles, monitor demand shifts closely, and use backward planning to realign schedules without creating instability. I stay in close communication with the Sales and Purchasing team to manage risks early and ensure materials are in place."

“The future of planning is the exact direction that I want my career to grow in – and GTK is the perfect place to be part of that shift.”

How does sustainability influence your planning decisions?

“Sustainability plays a key role in how I plan production. I minimise waste by planning only what is needed, when it’s needed, through backward planning and demand-driven scheduling.

“I group similar jobs to reduce set-ups and first-offs, control work-in-progress levels and align materials with the actual production plan to prevent rework or scrap.”

What do you see as the biggest opportunities for GTK's planning and operations?

“As a Production Planner, I see a major opportunity to integrate systems into one platform, providing real-time shop-floor visibility.

“This would improve planning accuracy, increase responsiveness to issues, and improve alignment between planning and operations, while reducing manual work and firefighting.”

Finally, what excites you the most about the future of production planning at GTK and across UK manufacturing?

“How things are moving toward smoother, smarter planning. With the mix of products and the fast pace, there’s a lot of opportunity to streamline processes, spot issues earlier and improve day-to-day flow – that’s the kind of work I get really excited by.

“Across UK manufacturing, everything is becoming more digital and more data-driven, while supply chains are becoming more resilient. Planning is no longer just firefighting; planning is strategic and forward-thinking.

“The future of planning is the exact direction that I want my career to grow in – and GTK is the perfect place to be part of that shift.”